Expediting productivity—and impact

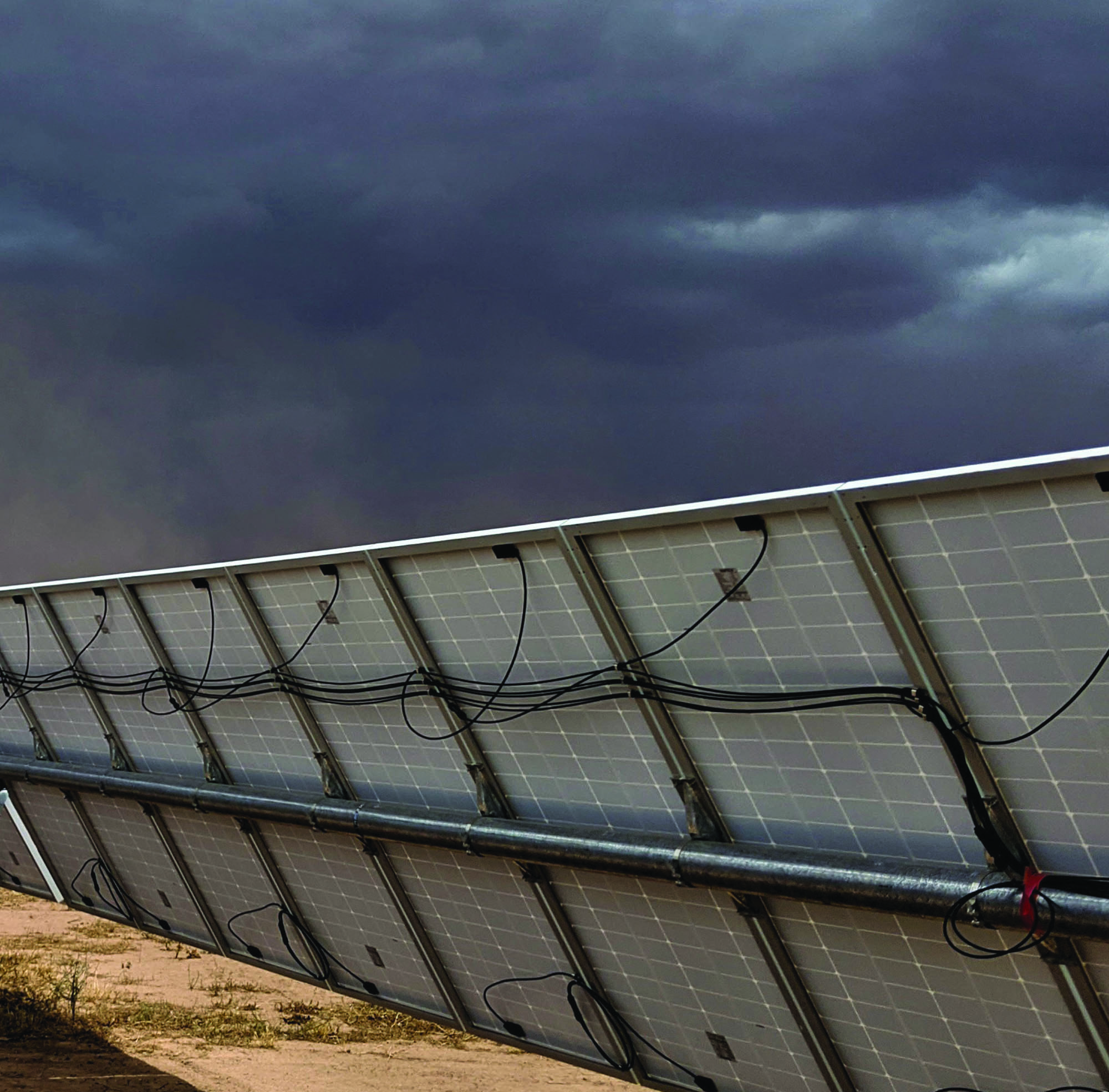

Ampacity’s focus on ground-mounted single-axis solar tracker projects, along with robust market growth and increased customer demand volume, led us to develop and streamline material sorting and kitting to keep up with faster construction schedules while focusing on error reduction, parts loss, and construction and uniformity.

We designed our proprietary tracker row boxes based on lessons learned from receiving and building trackers in the field. Our pick-pack-ship strategy moves the process of shaking out tracker material into a controlled warehouse environment and saves time and effort for construction teams.

By pre-assembling, boxing, and labeling materials prior to shipment, we reduce exposure to field conditions, streamline construction schedules, and improve installation efficiency by up to 50%.

Download PDF