The passing of the budget reconciliation bill H.R. 1—dubbed the “One Big Beautiful Bill Act (OBBBA)”—marked a pivotal moment in U.S. energy policy. The bill’s sweeping repeal of many renewable energy subsidies raised alarms across the clean energy sector. Since its passage in July, the industry has been adjusting to the new landscape ushered in by the OBBBA.

Since the OBBBA was passed in July, stakeholders across the solar industry have been developing strategies to secure tax credits for their projects, validate compliance with new procurement restrictions, and position themselves for success on an unsubsidized basis once the deadlines have passed and safe harbor projects are complete.

Given the work that the industry has done to reorient around the OBBBA since July, the tone at RE+ in Las Vegas last week was not one of “doom and gloom,” but of determination. Our industry is highly accustomed to change, and projects still need to be originated, permitted, designed, and built. Make no mistake, the OBBBA poses a threat to generation capacity additions at a time when we need more electrons than ever. Now that it has become law, it’s on the private sector to innovate, execute, and deploy better than ever before.

We’ve provided below a summary of key new policies as they pertain to planned community- and utility-scale solar projects in the United States:

New Investment Tax Credit (ITC) guidance

Under H.R. 1, the Investment Tax Credit (ITC) timelines for solar projects were significantly shortened. Before H.R. 1 was enacted, tax credits were anticipated to continue through 2032. While H.R. 1 did not fully eliminate tax credits, it accelerated their phase-out. This unexpected change has presented significant challenges for long-term solar initiatives. H.R. 1’s tight timelines require careful project planning and execution. The new ITC timelines are as follows:

- Projects that begin construction before July 4, 2026, are eligible for the full 30% ITC, with a four-year window to be placed in service.

- Projects beginning construction after July 4, 2026, must be placed in service by December 31, 2027, to qualify for any ITC.

- Solar projects that begin construction after July 4, 2026, and are placed in service after December 31, 2027, are not eligible for the ITC.

- Storage projects, including those co-located with solar, are eligible for the ITC for projects starting construction before 2033, with a phase-out schedule beginning in 2034.

- The ITC for storage projects begins phasing down for projects commencing construction in 2034 (75% of the credit) and 2035 (50% of the credit).

Additional Foreign Entity of Concern (FEOC) rules

Building on the Inflation Reduction Act (IRA), H.R. 1 extends foreign entity of concern (FEOC) restrictions to include additional clean energy tax credits. It also expands the definition and criteria of a FEOC, creating two new FEOC categories: Specified Foreign Entities (SFEs) and Foreign Influenced Entities (FIEs). Both categories are considered Prohibited Foreign Entities (PFEs). Any PFE is an FEOC.

Restrictions apply to SFEs, nations like China, Iran, North Korea, and Russia, and to FIEs that meet certain ownership or control thresholds or have specific contractual agreements with an SFE. The intent is to reduce U.S. reliance on these nations for clean energy supply chains and to prevent their influence over U.S. energy production.

Beginning January 1, 2026, any project or company deemed an SFE or FIE is not eligible for tax credits. Any project claiming tax credits must adhere to strict source restrictions that limit how much of its materials and components can originate from FEOCs. In other words, projects cannot receive tax credits if they involve “material assistance” from FEOCs, which includes sourcing components or providing financial or licensing agreements that involve these entities.

Projects must adhere to the following material assistance cost ratio (MACR) thresholds:

- Power facilities (45Y/48E): Minimum domestic sourcing starts at 40% in 2026, rising each year to 60% by 2030.

- Energy storage: Starts at 55% domestic, rising to 75% by 2030.

- Solar components manufacturing (45X):

- Solar components: 50% (2026) → 85% (2030)

- Inverters: starting at 50%, rising to 70%

- Battery components: 60% → 85%

Non-compliance with these thresholds disqualifies a project from receiving tax credits.

Projects relying on foreign supply chains face steep penalties or disqualification unless they meet these thresholds. As a result, developers now require deep visibility into their supply chains—specifically, the origins of every component—to certify compliance. Although U.S. solar manufacturers may gain from decreased foreign competition, the implementation of more stringent regulations and unclear eligibility requirements may deter investment and hinder future growth.

H.R. 1’s new provisions raise the bar for domestic content but introduce new complexities, tighten timelines and compliance documentation, and put added pressure on manufacturers and developers. How exactly these rules will be applied remains an open question, and the FEOC restrictions will continue to be a significant area of uncertainty for developers until more guidance is released.

New safe harbor guidance

On August 15th, 2025, the Department of the Treasury released new ITC safe harbor guidance that narrowed the definition of “start of construction,” specifically by eliminating the 5% rule for solar projects larger than 1.5MWac.

Around each of the changes to the ITC framework that have occurred since its introduction in 2006, safe harbor strategies have played a key role, providing developers with a path to certainty despite pending changes in the tax regime. This time around, safe harbor tools are more limited, though many developers have successfully safe harbored significant volumes of projects before the September 2nd deadline described below.

Effective September 2nd, 2025, the new guidance is as follows:

- Projects greater than 1.5 MWac in capacity must use the Physical Work Test path. The 5% rule no longer applies to projects of this size.

- The Physical Work Test is narrowed and does not include “preliminary activities.” Instead, the project must begin “physical work of a significant nature,” such as on-site construction activities like the installation of racking or other structures, or off-site work of a significant nature, such as the manufacturing of equipment, like certain transformers, that are tailored to the specific facility. Preliminary activities, like permitting or land grading, are not typically considered sufficient.

- Projects using Physical Work Test are subjected to a continuity requirement in which the project must show a “continuous program of construction,” where the “physical work performed is of a significant nature.”

- Projects less than 1.5 MWac in capacity (low-output projects) can use the Physical Work Test or the 5% Safe Harbor, in which a project qualifies if it has incurred at least 5% of the total project cost.

- All projects still have four years to be placed in service under Continuity Safe Harbor.

The new rules apply only to solar facilities whose construction did not begin before September 2, 2025. If a project started construction before this date using the old Physical Work Test or Five Percent Safe Harbor, those old rules still apply. If a project hasn’t started by September 2, 2025, then these tighter rules—including the end of the general 5% Safe Harbor—will govern whether a project meets the July 5, 2026, start of construction deadline.

In short:

- Started before Sept 2, 2025 → old safe harbor rules still apply

- Start on or after Sept 2, 2025 → must follow new Physical Work Test-only rule (except for projects ≤1.5 MWac solar)

A new solar landscape

Despite the hurdles presented by H.R. 1’s becoming law, our industry remains resilient. Solar energy consistently demonstrates its value as a reliable investment and remains the most rapidly deployable source of power generation. And our mission to accelerate the clean energy transition has never been more reinforced; It matters now more than ever.

Ampacity renews its commitment to providing reliable support as the industry adapts to this new solar landscape, ensuring clarity and stability for clean energy progress. We remain agile and dedicated to making clean energy accessible, reliable, and resilient, doubling down on our mission to:

- Help customers steer clear of permitting hurdles

- Provide quick design revisions with our expert in-house design and engineering teams

- Source domestically manufactured material from our partner manufacturers

- Accelerate deployment with turnkey solar and electrical solutions that reduce lead times and keep projects on schedule

- Perform physical work in the field

- Keep supply chains bolstered and ready to move

Now is the time to act and execute. Review your project needs and connect with us to see how we can help maximize the value of your pipeline: https://www.ampacity.com/contact/general-inquiries/

Disclaimer: The information provided in this article is for general informational purposes only and does not constitute tax, legal, or accounting advice. It is not a substitute for professional consultation with a qualified tax advisor, lawyer, or accountant who can address your specific financial situation. Ampacity makes no representations or warranties regarding the completeness, accuracy, or timeliness of the information provided. Any reliance you place on such information is strictly at your own risk. Ampacity will not be liable for any special, direct, indirect, consequential, or incidental damages or any damages whatsoever arising out of or in connection with the use of this information.

SOURCES:

Baker Tilly. “Understanding Foreign Entity of Concern.” Baker Tilly, 2025,

https://www.bakertilly.com/insights/understanding-foreign-entity-of-concern.

Crowell, Chris. “Explainer: New ‘Construction Start’ Definitions for Solar Projects (Notice 2025-42).” Solar Builder Mag, 18 Aug. 2025,

https://solarbuildermag.com/news/explainer-new-construction-start-definitions-for-solar-project-tax-credit-eligibility/.

Misbrener, Kelsey. “Final Budget Bill Advances to the President’s Desk.” Solar Power World Online, 3 July 2025,

https://www.solarpowerworldonline.com/2025/07/final-budget-bill-advances-to-the-presidents-desk-for-signature/.

Misbrener, Kelsey. “Senate Passes Budget Bill without Solar Excise Tax.” Solar Power World Online, 1 July 2025,

https://www.solarpowerworldonline.com/2025/07/senate-passes-budget-bill-without-solar-excise-tax/.

Misbrener, Kelsey. “SPW Talks with Tax Expert: Utility-Scale Solar Is Not Hit as Bad as You Think.” Solar Power World Online, July 2025,

https://www.solarpowerworldonline.com/2025/07/spw-talks-with-tax-expert-utility-scale-solar-is-not-hit-as-bad-as-you-think/.

“New Treasury Guidance Requires Large-Scale Solar Projects to Use ‘Physical Work Test’ for ITC Safe Harbor.” Solar Power World Online, Aug. 2025,

https://www.solarpowerworldonline.com/2025/08/new-treasury-guidance-requires-large-scale-solar-projects-to-use-physical-work-test-for-itc-safe-harbor/.

Solar Energy Industries Association (SEIA). “Solar and Storage Industry Statement on Final House Passage of the Reconciliation Bill.” SEIA, July 2025,

https://seia.org/news/solar-and-storage-industry-statement-on-final-house-passage-of-the-reconciliation-bill/.

“Trump Issues Executive Order Instructing Treasury to Tighten Safe Harbor Rules.” Solar Power World Online, July 2025,

https://www.solarpowerworldonline.com/2025/07/trump-issues-executive-order-instructing-treasury-to-tighten-safe-harbor-rules/.

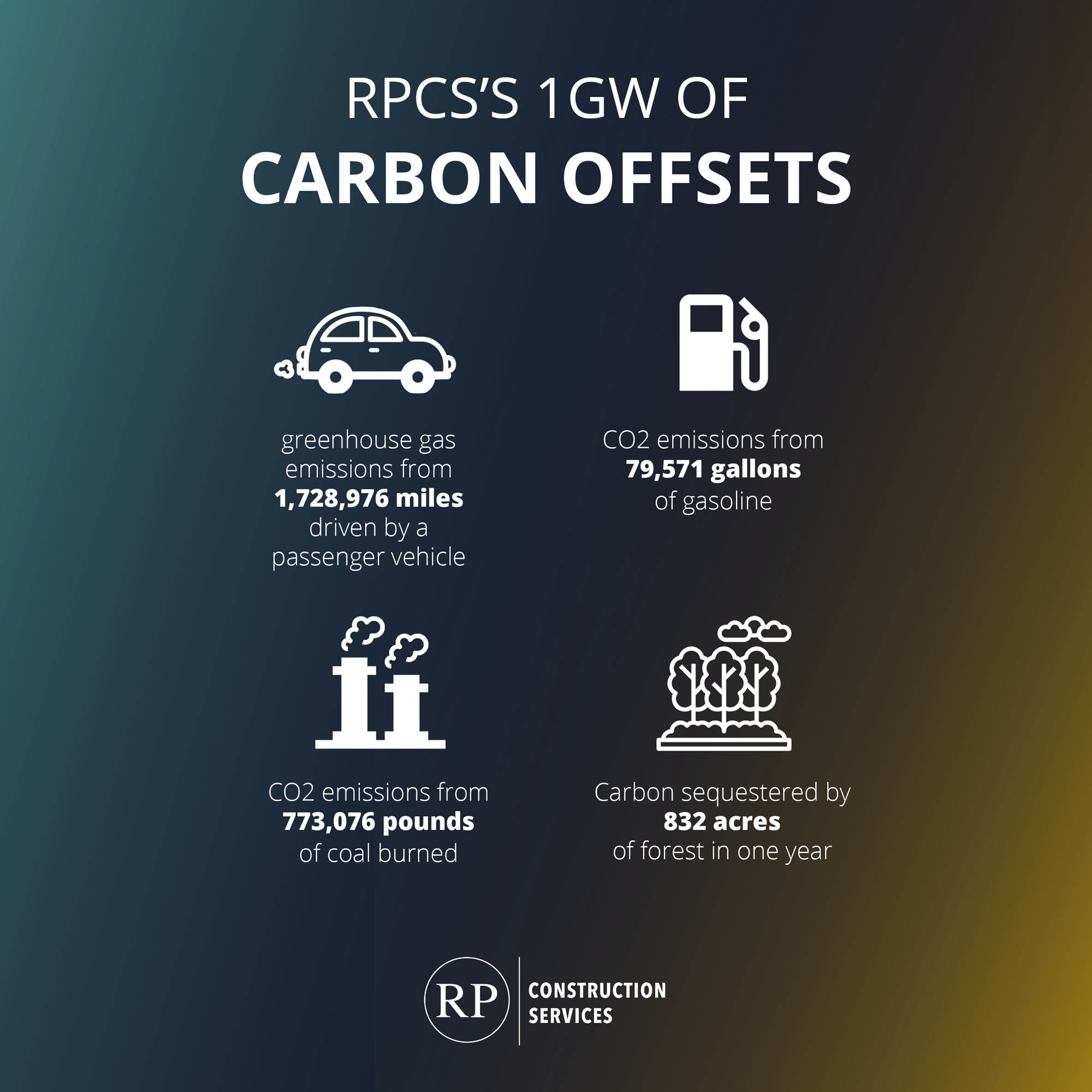

(MONTEREY, Calif.) JUNE 16, 2020 – RP Construction Services, Inc. (RPCS) and the Indiana Municipal Power Agency (IMPA) have partnered to build a number of solar tracker projects to supply communities throughout the state of Indiana with clean, renewable solar energy.

(MONTEREY, Calif.) JUNE 16, 2020 – RP Construction Services, Inc. (RPCS) and the Indiana Municipal Power Agency (IMPA) have partnered to build a number of solar tracker projects to supply communities throughout the state of Indiana with clean, renewable solar energy.

Ahead of the show’s start, RPCS members participated in the Run with the Sun 5K on Monday, spending the morning with 1,000 of their fellow solar friends. It was an exciting start to the week, with waterfalls and inclines leading to a spectacular sunrise over Salt Lake City.

Ahead of the show’s start, RPCS members participated in the Run with the Sun 5K on Monday, spending the morning with 1,000 of their fellow solar friends. It was an exciting start to the week, with waterfalls and inclines leading to a spectacular sunrise over Salt Lake City. On Monday night, RPCS was among the honorary guests in attendance at the Top Solar Contractors Gala, hosted by Solar Power World, where they were presented with an award for achieving a rank of No. 15 overall on the Top Solar Contractors list. Among their other rankings, RPCS placed No. 1 in the state of Georgia, No. 15 Utility Contractor, No. 4 Installation Subcontractor, and No. 11 Contractor in their home state of California.

On Monday night, RPCS was among the honorary guests in attendance at the Top Solar Contractors Gala, hosted by Solar Power World, where they were presented with an award for achieving a rank of No. 15 overall on the Top Solar Contractors list. Among their other rankings, RPCS placed No. 1 in the state of Georgia, No. 15 Utility Contractor, No. 4 Installation Subcontractor, and No. 11 Contractor in their home state of California. Throughout the show, there was lots of talk about RPCS’s Safe Harbor strategy with the end of the year–and the phase out of the solar investment tax credit–on the horizon. Earlier this summer, RPCS detailed their Safe Harbor strategy to allow project developers, financers, and owners to benefit from this year’s

Throughout the show, there was lots of talk about RPCS’s Safe Harbor strategy with the end of the year–and the phase out of the solar investment tax credit–on the horizon. Earlier this summer, RPCS detailed their Safe Harbor strategy to allow project developers, financers, and owners to benefit from this year’s